The Elkhart Brass second generation Electric Remote-Controlled Monitor (UL Class I, Div 2 ERCM) system design enables the use of a single PLC-based control panel to manage monitor and nozzle motor functions as well as serving as an Operator Control Panel (OCP).

Reliable Fire Protection Solutions for Industrial Locations

The UL Class I, Div 2 ERCM system is designed to provide a reliable industrial fire protection solution for Class I or Division 2 classified locations. The electric monitor and nozzle are FM Approved and the control panel is U.L. Listed.

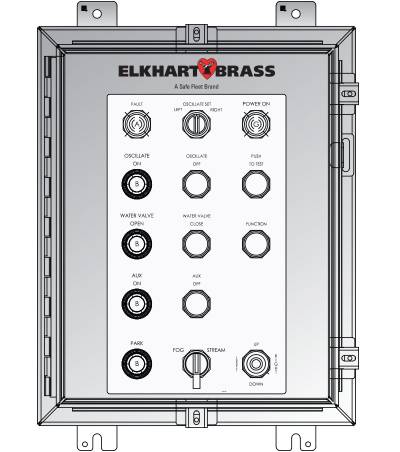

Standard Panel Features

ERCM Applications

Optional Networked Panel Features

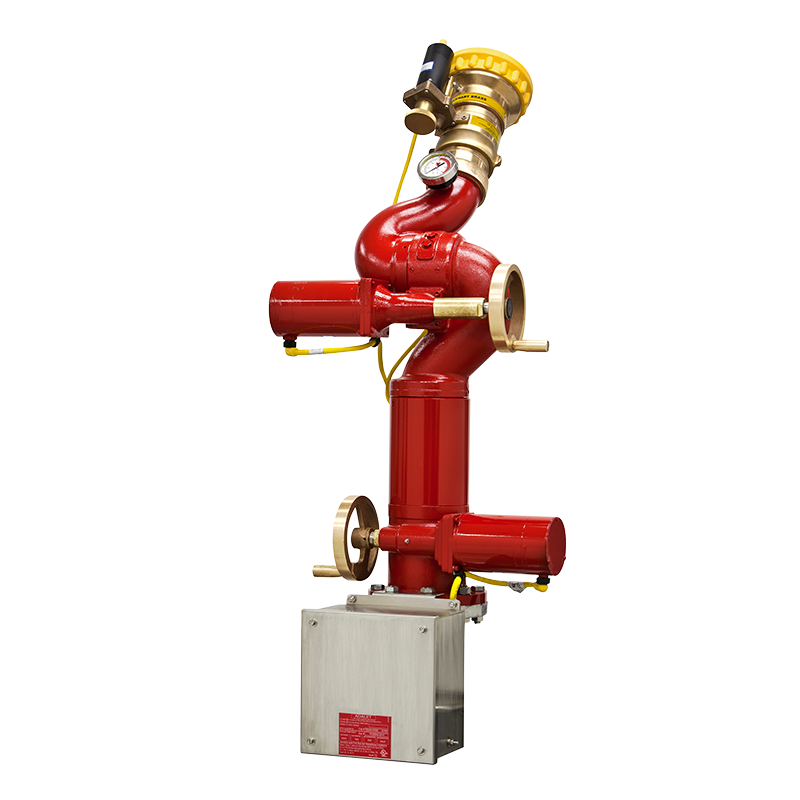

8394-053 Spit-Fire® Monitor

Industrial Electric Remote Controlled Monitor; 120VAC (60 Hz) Synchronous motors; 2,000 gpm (7,570 LPM) max flow rate; 200psi (14 BAR) maximum operating; -45° to +90° (135°) max vertical travel; 347° max horizontal travel; 4.0″ 150# ANSI flange inlet; 3.5″ NHT male outlet; 85 brass with red urethane enamel; suitable Class I Division 2 classified location application, FM Approved, NFPA 70 (NEC) compliant, NEMA 4X (IP66) junction box.

Main Control Panel (MCP)

Main Monitor Control Panel; Suitable for Class I Division 2 classified location; Factory configured for 3.2A@240VAC 60 Hz input power; factory configurable for 50 hz; field configurable for 120VAC or 480VAC; networkable; /Alarm Input / Group Response over ethernet network; 304 Stainless Steel NEMA 4x enclosure; UL Listed, complies with NFPA 70 (NEC).

- Optional 304 and 316 Stainless Steel NEMA 4x Enclosure or painted carbon steel NEMA 4 Enclosure

- Optional gland plate

- Optional multi-mode fiber optic network module

- Optional auxiliary device controls

Networked Operator Control Panel (OCP)

Optional Operator Control Panel (OCP); Suitable for Class I Division II classified location; 6.3A/3.2A @120/240VAC 50/60 Hz; networkable; Alarm Input / Group Response over ethernet network; 304 Stainless Steel NEMA 4x enclosure; UL Listed, complies with NFPA 70 (NEC).

- Optional Hazardous Location rated (Class I Division 2)

- Optional 304 and 316 Stainless Steel NEMA 4x Enclosure or painted carbon steel NEMA 4 Enclosure

- Optional gland plate

- Optional multi-mode fiber optic network module

- Optional auxiliary device controls

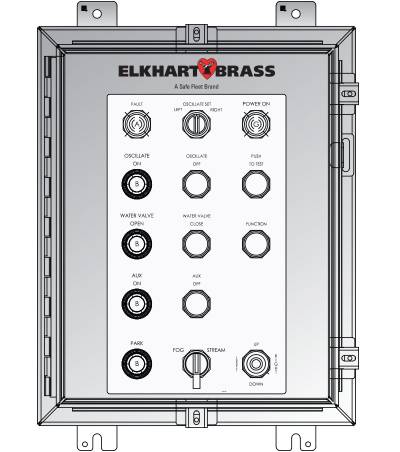

Hardwired Operator Control Panel

Optional Operator Control Panel (OCP); Power derived from MMCP; 304 Stainless Steel NEMA 4x Enclosure; UL Listed, complies with NFPA 70 (NEC).

- Optional Hazardous Location rated (Class I Division 2)

- Optional 316 Stainless Steel NEMA 4x Enclosure or painted carbon steel NEMA 4 Enclosure

- Optional gland plate

- Optional auxiliary device controls

GEN-II XT Extreme Temperature Panels available with higher temperature range

Optional RF Control

Optional RF control enables portable Radio Frequency (RF) control; 1000 feet (305 m) RF control range; networkable with up to 24 monitors per network system.

- Custom control buttons and switches are availableDiv. 2, Groups C and D, T5 Class II, Div. 2 Groups E, F, and G, Class III:T4

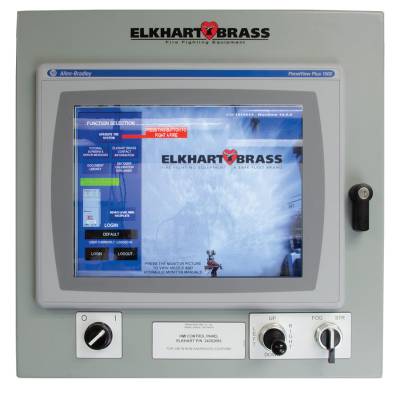

Optional Touch Screen Remote Control Console

Optional remote control console; 100-120VAC @ 2.1A input power; painted carbon steel; touch screen; supports up to 128 monitors.

- 220-240VAC @ 1.0A optional input power

- Optional wall-mount, free-standing console, or desktop

- Consolette enclosures

- Optional fiber communication connections

- Optional EWON device (for remote system access for troubleshooting and support)

- Optional Ergonomic Multi Axis Joystick (on free standing console only)

Optional Motor Operated Valve (MOV)

- 4.0″ Electric Butterfly Valve

- Can be used on remote controlled monitor systems

- Temperature range: -40 to 149°F; Stainless Steel valve with EPDM seat; 120-240VAC 50/60 Hz., 1-phase operating power; NEMA 4, 4x and 6, IP66/68; operating pressure – 150 PSI

- FM Approved: Class I Zone 1; AEx/Ex de IIB T5: Acceptable for Class I, Div. 2, Groups C and D, T5 Class II, Div. 2 Groups E, F, and G, Class III:T4