The Elkhart Brass fully automated, remote-controllable and configurable HydroBlast™ monitor is designed to provide the flexibility and reliability required for automatic mining vehicles and equipment washdown, aircraft wash and non-classified location fire suppression applications.

Designed for frequent, repeated and multi-spray pattern applications, the HydroBlast is equipped with seal and bearing designs that provide ultimate protection against fine mining dust and water ingress to ensure durability. In addition, the HydroBlast system offers programming and configuration flexibility that enables customers to choose from utilizing the HydroBlast remote control system or using customer plant PLC control unit to control the functions of the HydroBlast system. The HydroBlast system is feature rich and offers the industry’s most cost-efficient and reliable solutions in its class.

Key Features

Hydroblast Applications

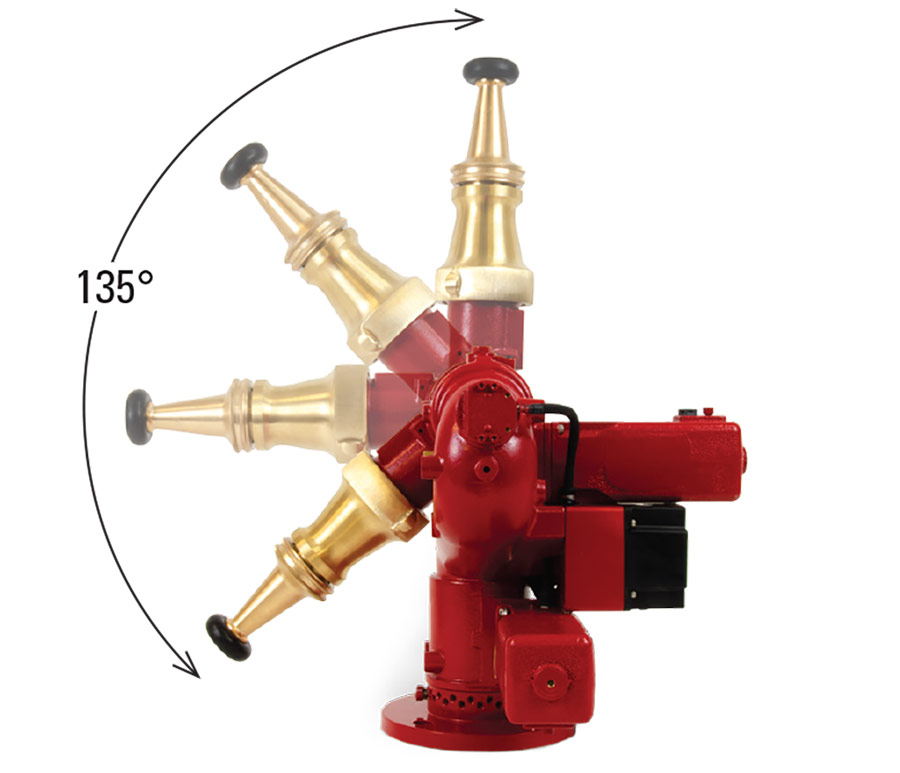

Vertical Motion

-45° to +90° Oscillation

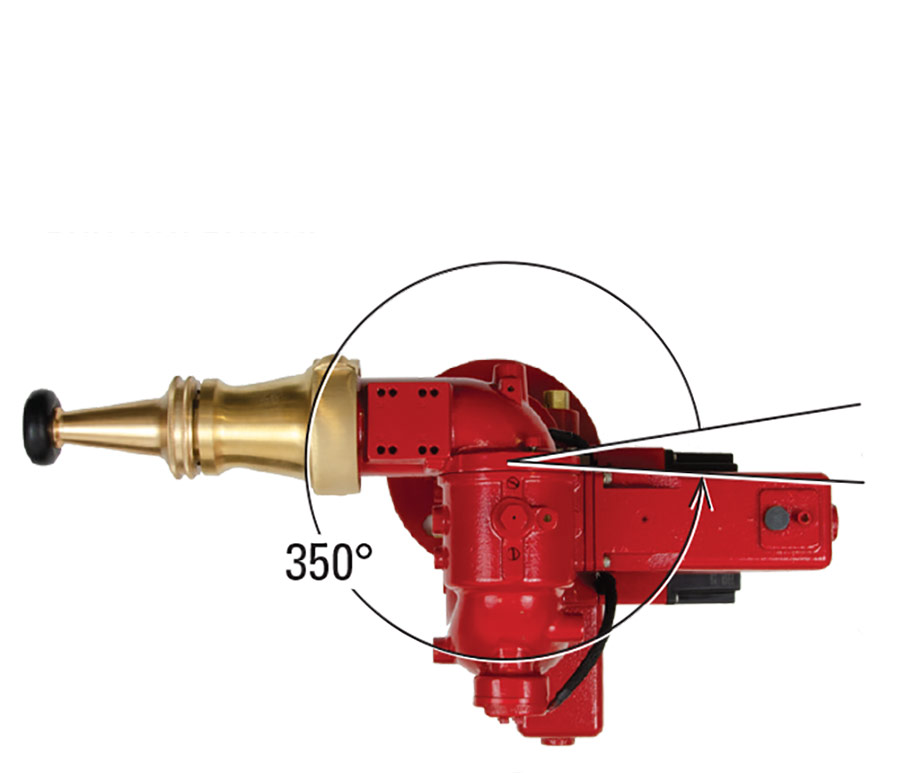

Horizontal Motion

350° Horizontal Oscillation

Reduced Wear

Thrust rods and bearings reduce wear on joints to improve life cycle and durability.

System Monitor Options

HydroBlast™

- Rated up to 750 gpm (2900 LPM)

- Rugged 85 brass construction

- Heavy-duty use

Sidewinder® EXM2

- Rated up to 750 gpm (2900 LPM)

- Teflon-impregnated hard-coated finish

- Lightweight aluminum construction

Cobra™ EXM2

- Rated up to 1250 gpm (4750 LPM)

- Teflon-impregnated hard-coated finish

- Lightweight aluminum construction

Scorpion® EXM2

- Rated up to 2500 gpm (9500 LPM)

- Teflon-impregnated hard-coated finish

- Lightweight aluminum construction

HydroBlast Monitor System

Designed for frequent, repeated and multi-spray pattern applications, the HydroBlast is equipped with seal and bearing designs that provide ultimate protection against fine mining dust and water ingress to ensure durability.

- Field programmable HMI touch screen for managing the functions of up to 16 independent monitors

- Learn feature via joystick operation enables field configuration of spray patterns for fire suppression and wash down applications

- Real time troubleshooting via HMI control unit enables system diagnostics from remote location

- Heavy-duty 85 brass for corrosive and non-corrosive environment applications

- Lightweight Teflon impregnated hard anodized aluminum monitors for non-corrosive environment applications